To mint a coin means to manufacture it at a facility called a mint . It’s a precise and intricate process that transforms raw metals into the currency we use daily.

Here’s a breakdown of the coin minting process:

- Design and Engraving: The process starts with a design, often approved by government authorities. A large plaster model is created, then transformed into a detailed 3D sculpture, [according to Global Coin] . This serves as the basis for the coin’s design. The approved design is then engraved onto a steel die . A die is a metallic piece used to strike a coin, containing an inverse version of the image to be imprinted.

- Blanking: Coils of metal are straightened and fed into a blanking press, which punches out circular discs called blanks . These blanks are the foundational pieces for the coins.

- Annealing: The blanks are heated in an annealing furnace to soften the metal, making it more malleable and easier to shape during the striking process.

- Cleaning and Drying: The annealed blanks undergo a chemical wash to restore their original color and remove impurities. They are then dried, preparing them for the next stage.

- Upsetting: An upsetting mill creates a raised rim around the edge of the blank, [says the U.S. Mint] . This rim protects the coin’s design and makes it easier to stack. A blank with a rim is called a planchet.

- Striking: The planchets are then fed into coining presses where the obverse (front) and reverse (back) dies strike the planchets simultaneously, impressing the design onto both sides of the coin. Modern presses use tremendous pressure, and circulating coins are struck at rates of hundreds per minute.

- Quality Control and Distribution: After striking, the coins undergo inspection to ensure they meet quality standards. They are then counted, weighed, and packaged for distribution, [according to the U.S. Mint].

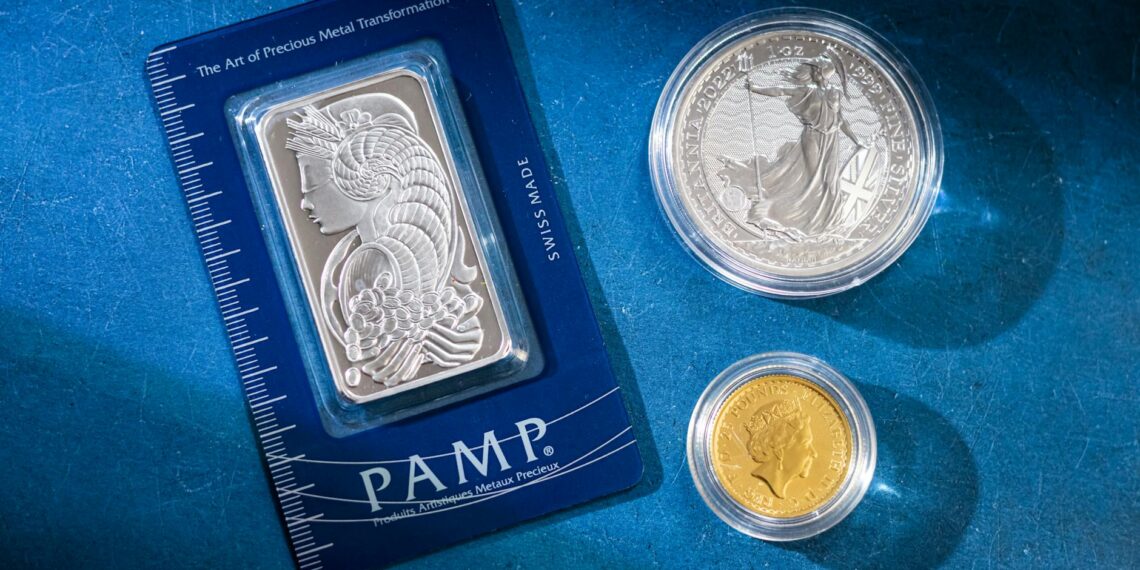

Essentially, minting is the act of producing physical coins, whether for circulating currency, commemorative editions, or for collectors.

What happens when a coin is minted?

The Mint has several different kinds of presses, but they all work the same way. The press forces the obverse and reverse dies together against the planchet to strike both sides of the coin at once. Circulating coin presses use from 35 to 100 metric tons of pressure to strike the coins, depending on the denomination.

Does it cost money to mint a coin?

Great question! How much does it cost to produce pennies? In fiscal year 2024, it took 3.7 cents to produce and distribute one penny, according to the 2024 U.S. Mint report.